Umbhobho wentsimbi engenamthungo

Inkcazelo emfutshane:

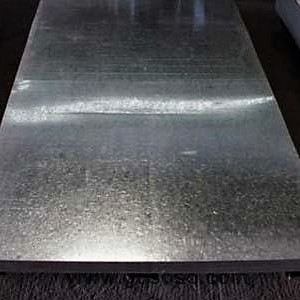

Ubungakanani bombhobho wesinyithi owenziwe ngamazi angenamthungo buncinci kakhulu, kuphela i-10-50g / m2, kwaye ukuxhathisa kwayo kokubola kwahluke kakhulu kulowo wombhobho oshushu-dip.Abavelisi bemibhobho ehlala igalvanized rhoqo bavumelekile ukuba basebenzise imibhobho enamanzi abandayo njengemibhobho yamanzi neyegesi.Uluhlu lwezinki lombhobho wensimbi obandayo luyi-electroplating layer, kwaye i-zinc layer ihlukaniswe kwi-substrate yombhobho wensimbi.Uluhlu lwe-zinc luncinci, kwaye i-zinc layer ifakwe nje kwi-matrix yepayipi yensimbi, elula ukuwa.Ngoko ke, ukuxhathisa kwayo kukonakala.Kwizindlu ezitsha, akuvumelekanga ukusebenzisa imibhobho yentsimbi ebandayo njengemibhobho yentsimbi yokubonelela ngamanzi.

Emva kokuchola, imibhobho yensimbi engenamthungo ye-API icocwa kwi-ammonium chloride okanye i-zinc chloride isisombululo se-aqueous okanye i-ammonium chloride kunye ne-zinc chloride exutywe kwitanki yesisombululo esinamanzi.Ukuze kuqinisekiswe umgangatho, i-electro galvanizing (i-cold plating) ayisetyenziswa kakhulu.Kuphela loo mashishini amancinci anezixhobo ezincinci kunye nezixhobo ezindala asebenzisa i-electro galvanizing, ngokuqinisekileyo, ixabiso labo lincinci.UMphathiswa wolwakhiwo uphelise ngokusesikweni umbhobho wegalvanized ongasemva obandayo, ongazukwenziwa i-electrogalvanized kwixesha elizayo.Kukwenza ukuba isinyithi esityhidiweyo siphendule nge-matrix yentsimbi ukuvelisa i-alloy layer, ukwenzela ukudibanisa i-matrix kunye ne-coating.Idiphu eshushu yokugalela intsimbi kukuchola umbhobho wentsimbi kuqala, ukuze kususwe i-oksidi yentsimbi kumphezulu wombhobho wentsimbi, uze uyithumele kwitanki yediphu yokugalela eshushu.I-Hot dip galvanizing ineenzuzo zokugquma okufanayo, ukunamathela okuqinileyo kunye nobomi benkonzo ende.