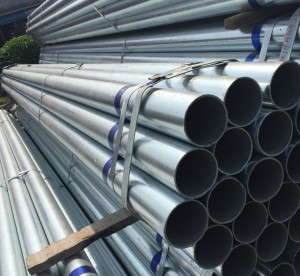

Idiphu eshushu ifakwe i-I-beam

Inkcazelo emfutshane:

Idiphu eshushu ifakwe i-I-beam ikwabizwa ngokuba yi-Hot-dip galvanized I-beam okanye i-hot-dip galvanized I-beam.Kukuntywilisela i-I-beam egxothiweyo kwi-zinc etyhidiweyo malunga ne-500 ℃, ukwenzela ukuba i-zinc layer ifakwe kumphezulu we-I-beam, ukuze kufezekiswe injongo yokuchasana nokubola.Ilungele zonke iintlobo zeemeko ezomeleleyo ezitshabalalisayo ezifana ne-asidi eyomeleleyo kunye nenkungu yealkali.

Iinzuzo zemveliso

1. Ixabiso eliphantsi lonyango: ixabiso le-galvanizing ye-hot-dip kunye nokukhusela i-rust iphantsi kunezinye iipeyinti zepeyinti;

2. Ihlala ixesha elide: intsimbi yentsimbi ene-galvanized angle eshushu ineempawu zeglosi yomphezulu, i-uniform zinc layer, akukho plating ingekhoyo, ithontsiza, incamathela eyomeleleyo kunye nokumelana nomhlwa.Kwimeko-bume yedolophu, ubungqingqwa obuqhelekileyo bokudipha be-galvanized antirust bunokugcinwa ngaphezu kweminyaka engama-50 ngaphandle kokulungiswa;Kwiindawo ezisezidolophini okanye ezingaselunxwemeni, umgangatho we-antirust oqhelekileyo wokudipha unokugcinwa iminyaka engama-20 ngaphandle kokulungiswa;

3. Ukuthembeka okulungileyo: i-zinc yokugqoka kunye nentsimbi idibaniswe nge-metallurgically kwaye ibe yinxalenye yentsimbi yentsimbi, ngoko ukuqina kwengubo kunokwethenjelwa ngakumbi;

4. Ukuqina okuqinileyo kwengubo: i-zinc ifakela i-metallurgical structure ekhethekileyo, enokumelana nomonakalo womatshini ngexesha lokuthutha kunye nokusetyenziswa;

5. Ukukhuselwa okubanzi: yonke inxalenye yecandelo elidibeneyo linokuthi lifakwe nge-zinc, kwaye linokukhuselwa ngokupheleleyo nakwii-depressions, iikona ezibukhali kunye neendawo ezifihliweyo;

6. Ukugcinwa kwexesha kunye nokugcinwa kwabasebenzi: inkqubo ye-galvanizing ikhawuleza kunezinye iindlela zokwakha zokugquma, kwaye ixesha elifunekayo lokupenda kwisayithi emva kokufakwa kunokugwenywa.